Range of Services

CheMin probes and sensors

– a unique chance to record and evaluate interactions in the running process

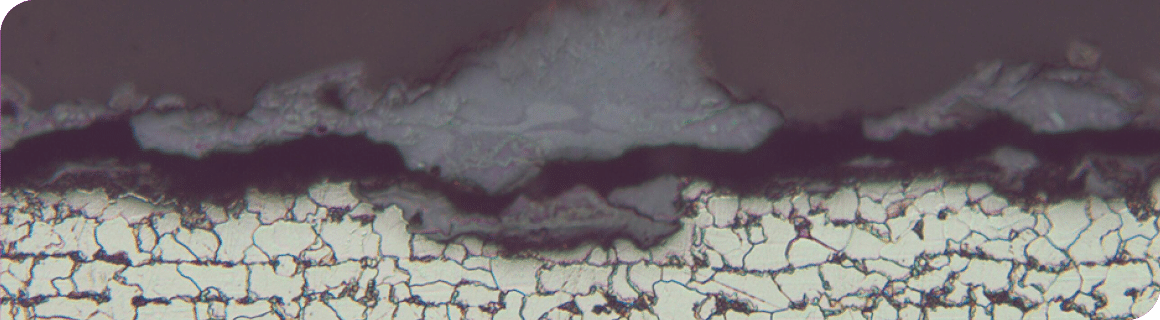

Working close to reality instead of in a laboratory environment – this is our way to demonstrate the performance characteristics of materials in the environment of chemical, thermal and mechanical interactions – much more clearly than it would be possible through laboratory tests on the test bench.

Our practical experience with corrosion and functional failure in steam generators or in flue gas cleaning shows that the environment there can be highly variable and unsteady. This makes it difficult to predict how the material in question will actually behave. Any test that is not based on ‘real’ environmental conditions thus offers only and inadequate basis for a decision.

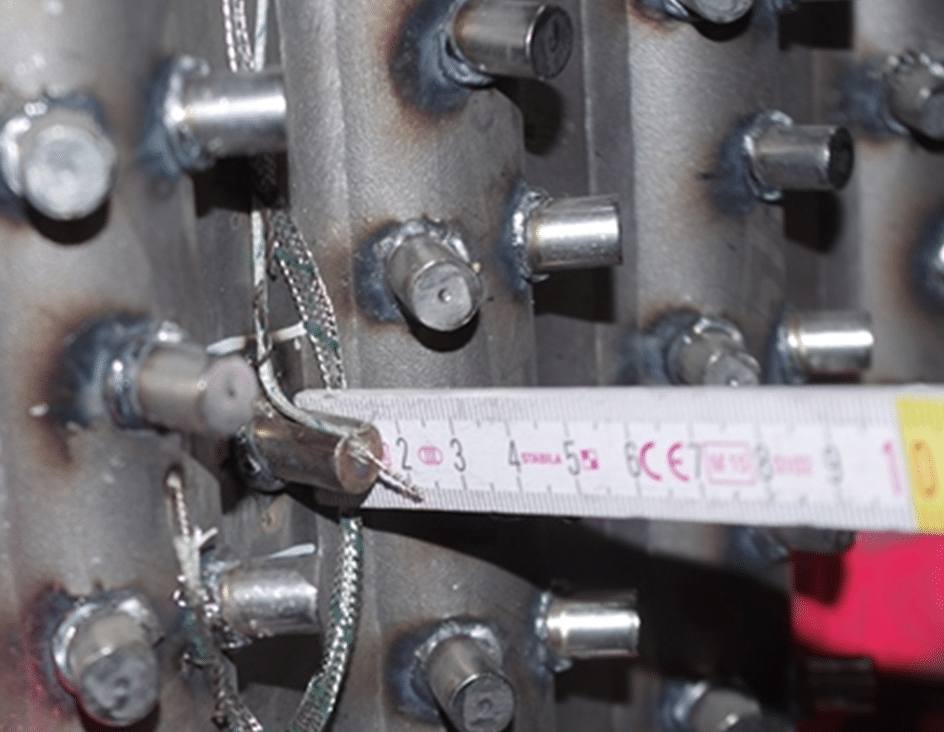

Since 2006, we are developing and building our own patented CheMin probe and temperature sensor technology, which we flexibly adapt to the precise task and the place of use.

This includes the Temperature-Range Probe (TRP), which is designed as a tube probe for use in superheaters and as a tube wall probe for use in evaporators. The TRP is suitable for various material, corrosion and coating investigations.

The CheMin temperature sensor system plays an important role in process optimisation in steam generators. It can be used to record the heat load or heat absorption of pipes and other components, so that suitable measures can be taken to achieve a more even and thus gentler load.

The CheMin range of probes also includes particle probes, such as the grid probe, which is inserted into the flue gas flow for only a few seconds. The deposited salts and ash provide information on corrosion and fouling behaviour. A corresponding particle probe is also available to determine the ash-salt proportion (ASP).

A highlight among the family of CheMin probes is our air-cooled mobile high-temperature camera probe, which can be used at short notice and in a targeted manner at a wide variety of positions along the flue gas path. It gathers optical information (both moving and still images) which can reveal optimisation potential in many ways.

Our latest developement is the sulphation probe. It is suited to determine the SO3 contents of the flue gas at various locations in the furnace. The information gathered allows to lower corrosion and fouling effects.

Our probes and sensors in detail:

Temperature-Range-Probe (TRP)

Temperature Sensor System

Particle Probes

Mobile high-temperature camera probe

Sulphation Probe