Range of Services

CEE Corrosion Environment Evaluation

– a holistic approach to reducing corrosion in boilers and an important component of optimisation strategies and risk management

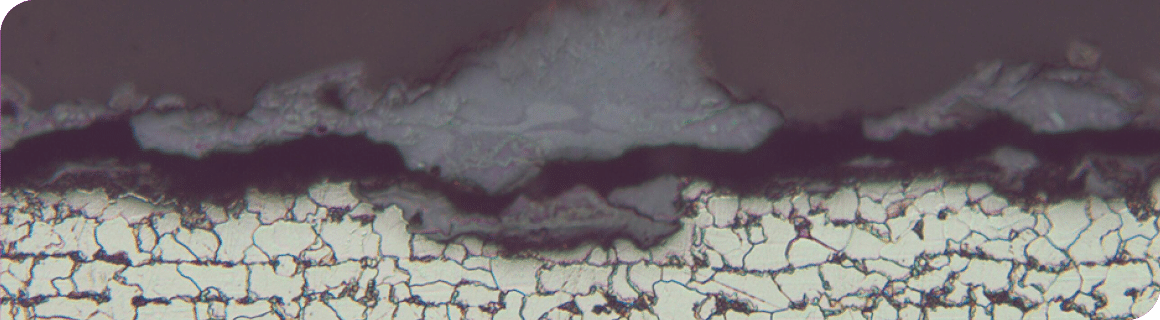

The CEE® (Corrosion Environment Evaluation) concept developed by CheMin is based on a holistic survey and assessment of the entire corrosion environment. It looks at the thermal, mechanical and chemical influences which plants that are operated with waste, substitute fuel and biomass are exposed to. We record these influences both during operation (online) and during standstill (offline).

Our measurements and analyses (a diagnosis) finally lead to an evaluation (a prognosis), from which measures can be derived (optimisation).

This procedure supports and accelerates adaptation processes that are triggered in existing power plants by various requirements, including

- Adaption of the existing operational situation

- Adaptation of fuel and/or firing

- Adaption of material protection concepts

- Adaptation of steam parameters

- Use of corrosion-reducing additives

These improvement measures ultimately serve to secure economic and ecological goals, such as

- lower maintenance costs

- higher availability

- longer service life and longer operation times

- higher energy efficiency

The holistic recording of interactions by means of CEE is of particular relevance in the first years of a boiler’s life. It is a matter of early recognition of risks and the potential for optimisation as well as of a deeper understanding of the chemical and thermal processes. This is an important building block for technical operation management with a high economic and ecological impact.