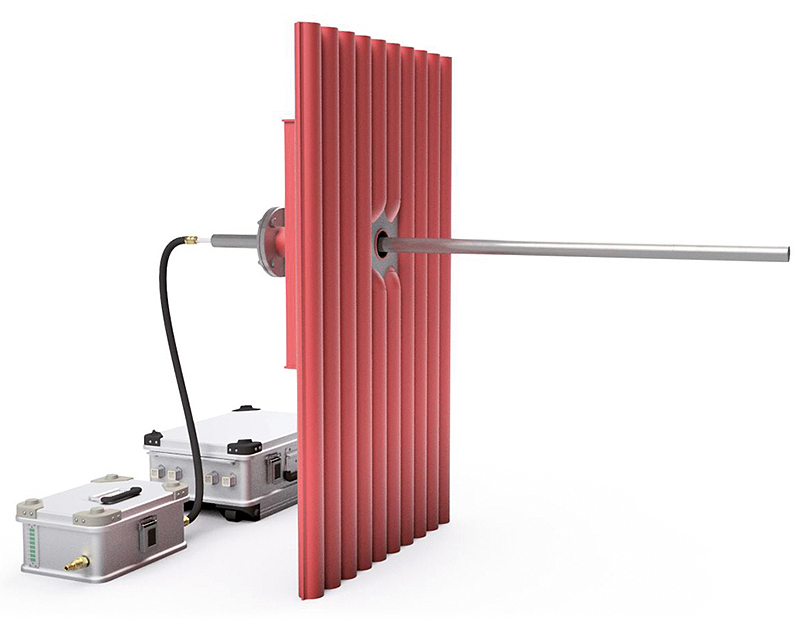

Temperature-Range-Probe (TRP)

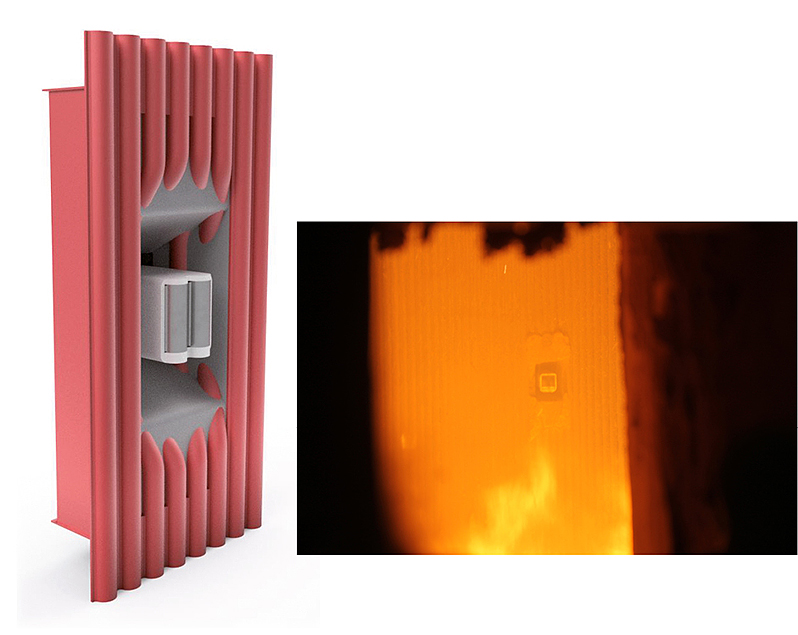

The body of the Temperature-Range-Probe is a component that corresponds to a boiler tube – either with an applied protective layer or made of protective layer material. It is named after the front part of the probe, which can be adjusted to a freely selectable, constant temperature range. This allows us to record the important parameters simultaneously over a wide temperature range and also to determine critical temperature thresholds.

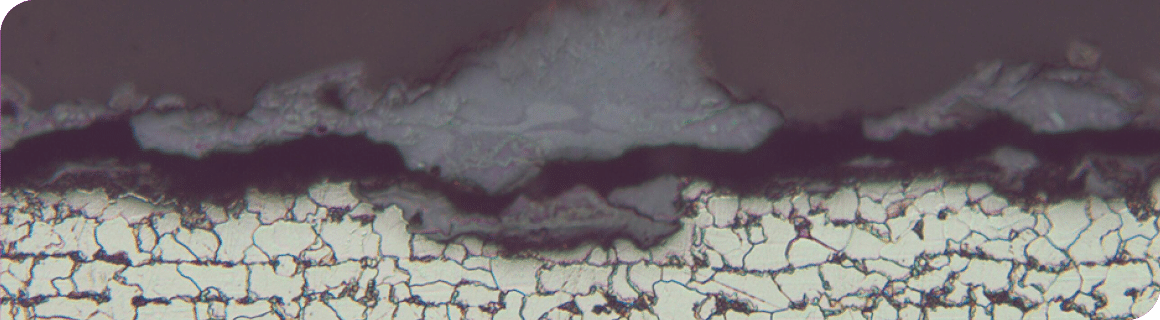

The TRP can be deployed and removed at any time. Depending on the task involved the duration of exposure can range from hours to months. In this way, specific or even several variable operating states can be mapped. After application, we dismantle the probe body in our laboratory if necessary and examine it on a micro analytical level to determine the cause, type and intensity of the corrosion or functional impairment.

The probe design of the TRP is suitable for a number of different types of examination. In addition to material tests, it can also be used to collect findings on the cause, mechanism and dynamics of corrosion and fouling. Application scenarios include the investigation of deliquescence corrosion, high-temperature chlorine corrosion, salt melt corrosion as well as thick and/or hard fouling.

Further information on the tube wall probe can be found in our flyer.

Further information on the tube probe can be found in our flyer.

Probe Carrier – Probe Head – Protective Tube

A combination of probe carrier and probe head has been developed for applying the Temperature-Range-Probe (TRP) to special cases. For this a modular structure is used. One probe carrier can be used for several tests and can be equipped with different probe heads. Thereby, the structure of the probe head can be shaped more easily and more economically.

This combination is especially suitable for several similar tests. Additionally, a protective tube can be installed for this combination as well as for the standard TRP. In this way, further degrees of freedom can be varied, such as depth of installation and positioning.